Flanged Ball Valves

Flanged Ball Valve

Flanged ball valve operation is simple and rapid, easy to disassemble and assemble. Products cover ANSI, DIN, JIS, GB standard, etc, a wide range of applications.

Specification: DN15-300(1/2”-12”)

Product certificates: API6D/608/607, CE, ATEX, SIL 2, Watermark, etc.

Applications

- Hydraulics

- Gas industry

- Environmental protection

- Pharmaceutical Chemicals

- Petroleum and petrochemical

Available

- Size: DN15-300(1/2”-12”)

- Material: CF8, CF8M, WCB, 1.4408, 1.4308, 1.0619

- Pressure: DIN(PN16/25/40/63/100), ASME(CLASS150/300/600), JIS (10K/20K)etc

- Standards: DIN, ASME, JIS, GB

Characteristics

- Light torque

- Long service life

- Easy to install

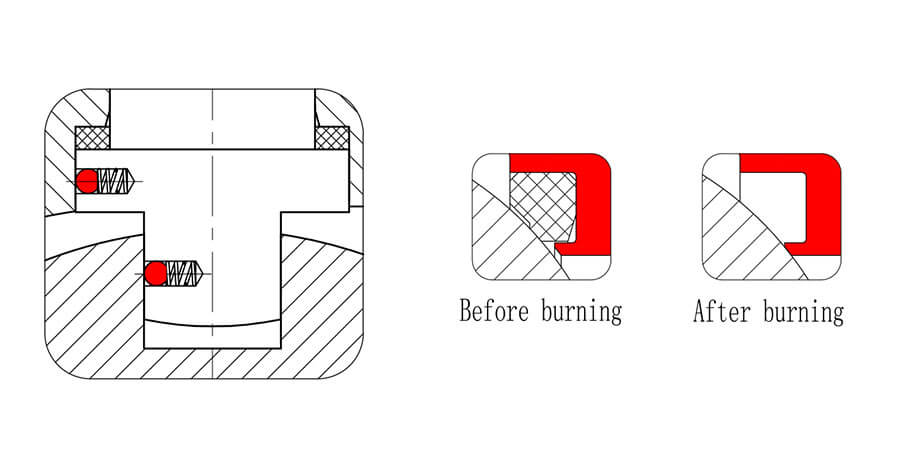

Excellent sealing performance

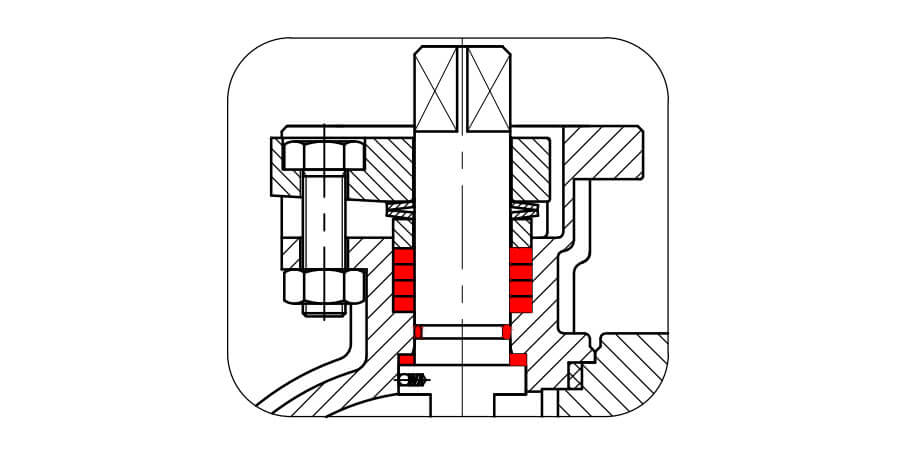

Stem multi-stage sealing, valve seat elastic sealing design

Safe and reliable

Valve stem blowout prevention, fireproof, explosion-proof, anti-static and other functions design

The torque is light and stable

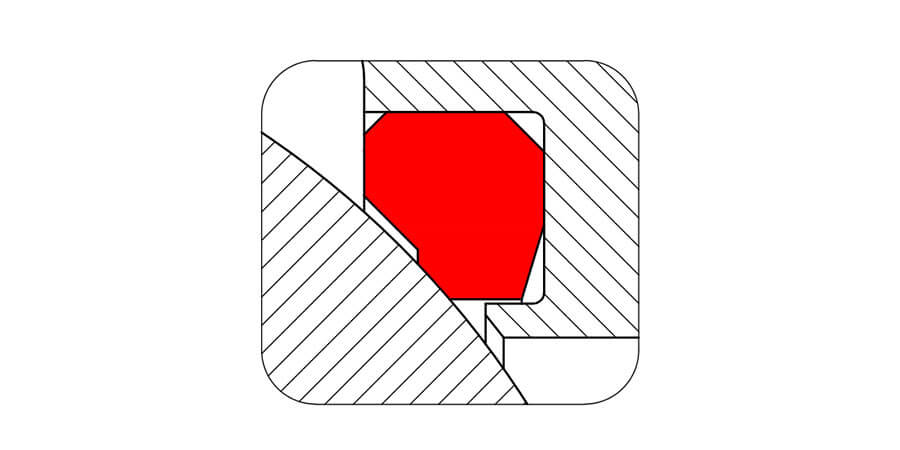

The valve seat sealing part adopts elastic structure design, easy opening and closing, torque wrench lock nut, torque value fluctuates up and down, no more than 10%

Double butterfly shrapnel device design

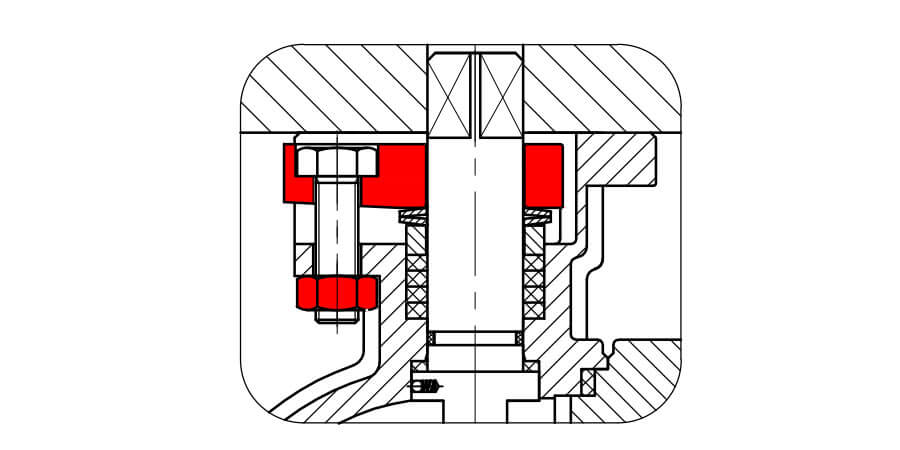

Convenient maintenance

Sunken gland design, more convenient maintenance.

Any kind of business solution or consultation don’t hesitate to contact.